A rethink of WEEE recycling can drive global metal supply circulatory, says Fernando Nuño, advisory board member for the upcoming electrical engineering exhibition and conference, CWIEME Berlin.

According to the UN, waste electrical and electronic equipment (WEEE) is the world’s fastest growing waste stream. In 2022, this waste contained metals like copper and aluminium that had an estimated worth of almost 100 billion dollars. Almost a quarter of this went to landfill that year, but that needn’t ever happen again.

In electrical manufacturing, the primary metals used are copper, aluminium and steel, plus others such as zinc, nickel and minor amounts of silver, gold and platinum. Obtaining enough of these metals to meet the global demand is already challenging, but demand is increasing year on year.

A shift to circularity, which reduces reliance on virgin materials by eliminating waste through improved recycling, can alleviate the financial costs and reduce the need for mining. It can also free industries from the effects of price volatility caused by supply chain disruptions and geopolitics. So why is the electrical manufacturing industry not already circular across the globe?

A closed loop

One of the biggest challenges in WEEE recycling is systematic collection and recovery. Many small motors, cables and electrical components end up in landfills or informal recycling networks, particularly in regions with weak infrastructure. Extended Producer Responsibility (EPR) schemes, which place legal responsibility on manufacturers to fund collection and recycling, could improve recovery rates but are inconsistently applied.

Separation poses another issue, particularly for metals that degrade when recycled. For example, recycled aluminium requires blending with virgin material to maintain quality, limiting its potential for circularity. Frequent use of alloys, some of which are more difficult to separate into constituent elements than others, also increases the risk of downcycling.

The other challenge is the regulatory inconsistencies that add yet another level of complexity. The modern global recycling market is complex and decentralised; different rules and classifications apply across regions. For example, the EU WEEE Directive defines six categories of electronic waste, but some member states still use older classifications based on the original ten categories from the 2012 directive. This can complicate cross-border recycling and allow materials to escape into unregulated supply chains.

A poster child for circularity

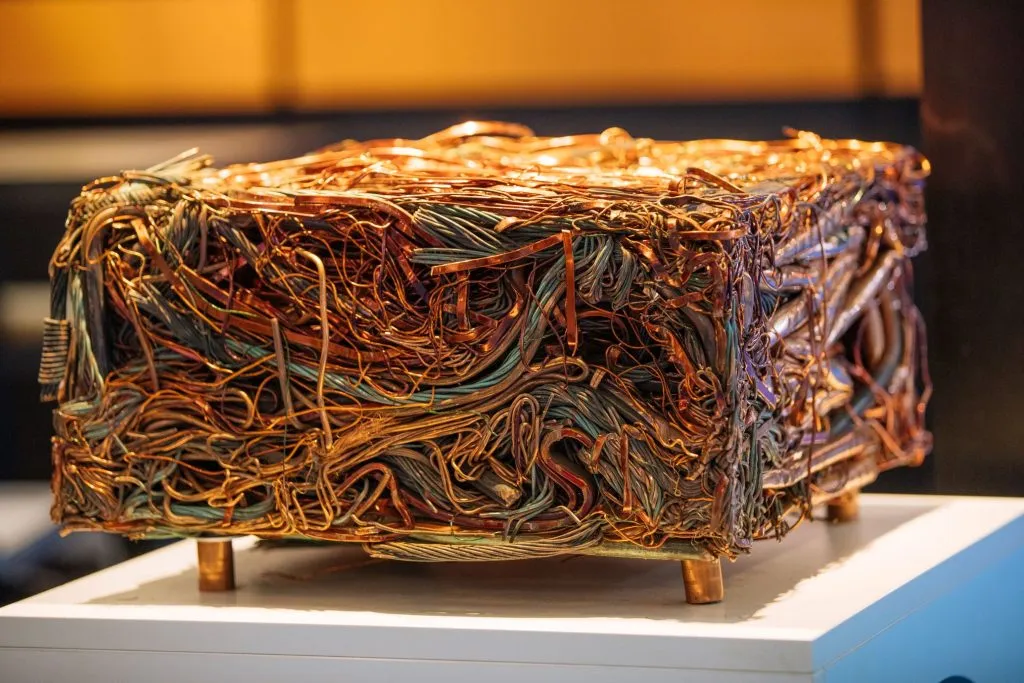

Copper could be the first material to reach a high degree of circularity. Unlike other materials, it can be recycled infinitely with no loss of quality. The idea is not new, and Europe already leads in copper recycling, with facilities such as Aurubis in Germany and Rönnskär in Sweden demonstrating the potential of advanced material recovery. Indeed, a more regional approach to recycling could enhance efficiency considerably. For instance, setting up dedicated recycling centres serving large areas could enhance the processing efficiency and cut transportation emissions.

Investing in improved recycling technologies is equally important. New technologies like AI-driven sorting systems and improved smelting methods enable better material separation that ensures copper and other valuable metals are recovered with minimum impurities. At the same time, policy makers could encourage design-for-recycling strategies that ensure that manufacturers develop products that can be easily taken apart and recycled at the end of their life cycle, with minimal energy and labour costs.

Greater cross-industry collaboration is essential. Manufacturers, recyclers and metallurgists must work together to improve material recovery. For instance, smelters can work with Original Equipment Manufacturers (OEMs) to develop products that use compatible elements and alloys, ensuring that valuable materials can be recovered efficiently.

CWIEME Berlin provides a vital platform for these discussions, bringing together industry leaders to explore the latest advances in circularity and metal recycling. Registration for the show is now open, and you can book a free ticket at berlin.CWIEMEevents.com.